MSTECH

Home Products > Automobile Assembly Line

Product

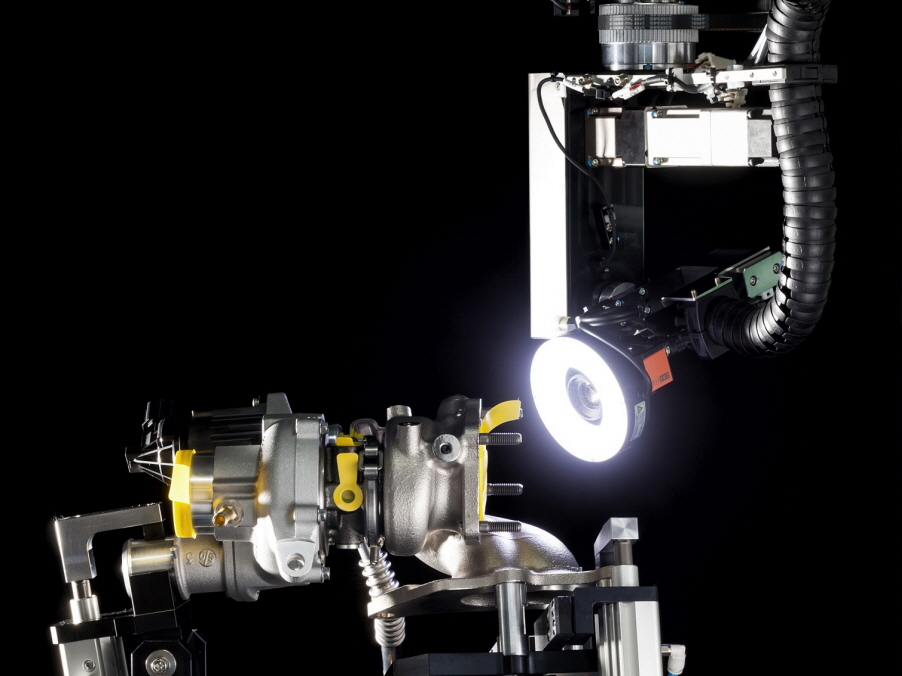

Vision Inspection System Vision Inspection System

Features

- Fool-Proof High-Precision Vision Inspection

- All 3-Dimensional Angle Inspection

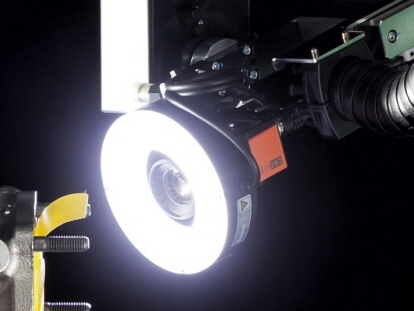

- High-Pixel Digital Camera & Lighting

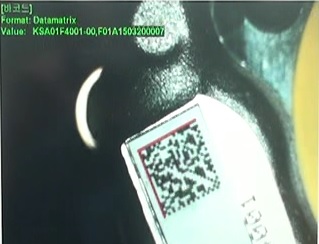

- Barcode(1D/2D) Scan

- Full Graphic UI & Inspection Display

- Various Ass’y Parts Inspection

- LMS & Database(DB) Interlock

Options

- Repair Table (Separated)

Features

-

- All 3-Dimensional Angle Inspection

- All 3-dimensional angles can be inspected by 5-axis (2 Theta) simultaneous control.

-

- High-Pixel Digital Camera & Lighting

- Precise and stable inspection is performed by high-pixel digital camera, lens and lighting control.

-

- Barcode(1D/2D) Scan

- By using Vision, 1D/2D barcode is scanned for interlock with Line Management System(LMS) and Data Base(DB).

-

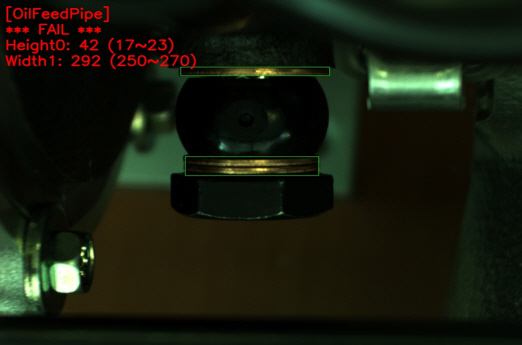

- Full Graphic UI & Inspection Display

- Full graphic UI based on Windows is applied for easy & simple operation.

Inspection process is displayed on monitor and inspection result is easily seen.

-

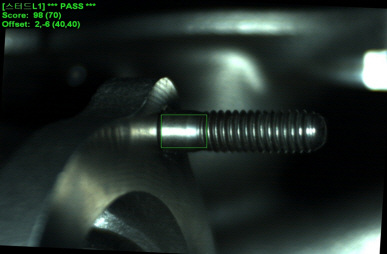

- Stud Bolt Inspection

- Stud Bolt is inspected for its missing, reversed assembly, incorrect bolt assembly, etc.

-

- Gasket / Washer Inspection

- Gasket & Washer are inspected for their missing, double assembly, incorrect gasket/washer assembly, etc.

-

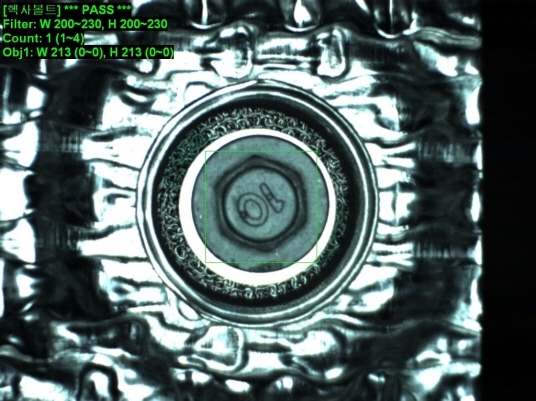

- Flange Bolt & Hexa Bolt Inspection

- Flange Bolt & Hexa Bolt are inspected for their incomplete assembly or missing, etc.

-

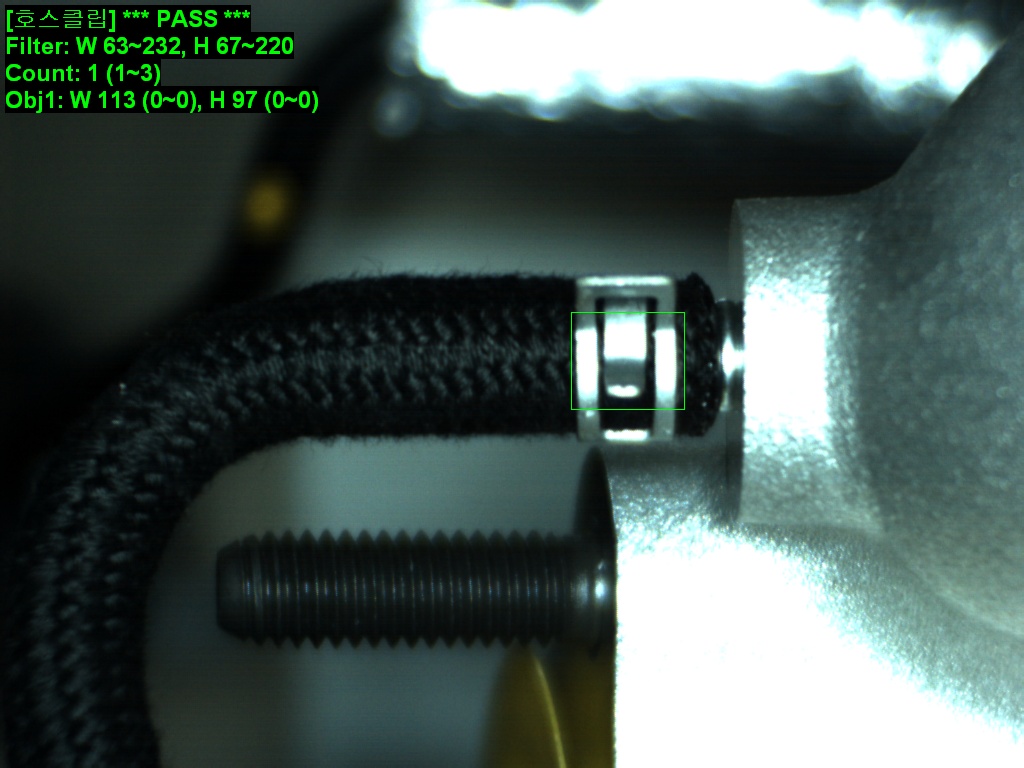

- Clip Inspection

- Clip is inspected for its incomplete or missing, etc.

-

- LMS & Database(DB) Interlock

- Pass or Fail result during Vision Inspection is saved at Database(DB), and can be interlocked with Line Management System(LMS) for traceability.

Options

-

- Repair Table (Separated)

- In case of Off-Line Vision Inspection System, separated Repair Table can be used for repair of fail items.

Specifications(Standard)

Layout

Video